The logistics industry plays a pivotal role in global supply chains, ensuring goods and services move seamlessly from suppliers to consumers. As demand for efficiency, accuracy, and speed in deliveries grows, industries are turning to innovative technologies. One such transformative force is robotics, which is revolutionizing the way logistics operations function. From warehousing to last-mile delivery, robotics are changing the landscape of logistics, improving operational efficiencies, reducing costs, and enhancing customer experiences. In this post, we will explore how robotics is reshaping the logistics sector.

1. The Need for Transformation in the Logistics Industry

Logistics is a rapidly growing industry driven by e-commerce, global trade, and consumer demand for faster deliveries. The logistics sector is complex and involves multiple processes such as inventory management, order fulfillment, packaging, shipping, and transportation. Traditional methods, relying heavily on human labor, have limitations, including:

- Inefficiencies: Human workers can only handle a limited number of tasks, leading to slowdowns and bottlenecks in operations.

- Error-prone: Manual processes are more susceptible to mistakes, whether it’s inventory tracking, picking, or packaging.

- Labor Shortages: The logistics industry is facing a significant shortage of labor, especially with the growing demand for e-commerce.

- High Costs: Labor costs, transportation, and infrastructure maintenance account for a large percentage of logistics expenses.

To address these challenges, companies have increasingly turned to automation and robotics. The integration of robotic systems has led to a transformation in warehouse management, order picking, inventory control, and transportation.

2. Robotics in Warehousing and Inventory Management

Warehousing and inventory management are critical components of the logistics process. Robotics is making significant strides in these areas by increasing speed, accuracy, and cost-effectiveness.

Automated Guided Vehicles (AGVs): AGVs are mobile robots that transport goods within warehouses. They are equipped with sensors and software that help them navigate around obstacles and follow predefined paths. AGVs reduce the need for manual labor in transporting products across the warehouse, improving efficiency and freeing up human workers for higher-value tasks.

Robotic Arms: Robotic arms are being used in warehouses to automate repetitive tasks such as picking, sorting, and packing products. These robots are capable of working quickly and accurately, handling a wide range of products, from small components to large packages. Robotic arms are also often equipped with machine learning algorithms, which allow them to improve their picking abilities over time.

Drones for Inventory Scanning: Drones equipped with cameras and scanners can automate the process of inventory counting and tracking. Drones fly over shelves and use barcode scanning technology to update the inventory system in real-time. This technology greatly reduces the time it takes to conduct stocktakes and minimizes human error.

Robotic Sorting Systems: In a warehouse, goods need to be sorted based on various criteria, such as size, weight, or destination. Robotic sorting systems use AI and machine learning algorithms to identify and sort products efficiently. These systems can quickly process and sort thousands of items, reducing errors and improving overall productivity.

Collaborative Robots (Cobots): Cobots work alongside human workers in a shared environment. Unlike traditional robots that operate autonomously, cobots are designed to assist workers in tasks such as lifting, sorting, and picking. Cobots improve efficiency by supporting workers with heavy or repetitive tasks, allowing humans to focus on decision-making or tasks that require greater dexterity.

3. Robotics in Last-Mile Delivery

One of the most challenging and expensive aspects of logistics is last-mile delivery—the final leg of the delivery journey from the distribution center to the end customer. Robotics is transforming this process in a variety of ways, improving delivery speed and cost-effectiveness.

Autonomous Delivery Vehicles: Self-driving delivery vehicles, including trucks and vans, are revolutionizing the way goods are transported. These vehicles are equipped with sensors, cameras, and AI algorithms that enable them to navigate safely and deliver packages without human drivers. They can operate 24/7, reducing labor costs and improving efficiency.

Delivery Drones: Drones have gained significant attention as an innovative solution for last-mile delivery. These unmanned aerial vehicles can fly directly from warehouses to customer locations, bypassing traffic congestion and reducing delivery times. Drones are especially effective in rural or remote areas where traditional delivery methods may be slower and more expensive. Companies like Amazon have already tested drone delivery systems, and they are expected to become more widespread in the coming years.

Robotic Delivery Robots: Small, ground-based delivery robots are increasingly being deployed in urban environments to deliver packages to customers. These robots, which are often the size of a suitcase, can navigate sidewalks, cross streets, and deliver goods directly to customers’ doorsteps. Powered by electric batteries and equipped with GPS, cameras, and sensors, these robots are a sustainable and cost-effective alternative to traditional delivery methods.

Automated Parcel Lockers: Robotics is also playing a key role in the growth of automated parcel lockers. These self-service kiosks allow customers to pick up and return packages at their convenience. Automated parcel lockers use robotics to store and retrieve packages based on customer requests, streamlining the delivery process and providing greater flexibility for both consumers and logistics companies.

4. Robotics and Supply Chain Optimization

Robotics is also making waves in the broader supply chain by improving coordination and synchronization across various stages of production, transportation, and distribution. Key innovations include:

Robotic Process Automation (RPA): RPA is a form of automation that uses software robots to carry out rule-based tasks in business processes, such as order processing, invoicing, and inventory management. In the logistics industry, RPA can automate routine and repetitive tasks, allowing employees to focus on higher-level decision-making and customer service.

Blockchain and Robotics Integration: The integration of blockchain technology with robotics helps increase transparency and security in supply chain management. Blockchain provides an immutable record of transactions, allowing logistics companies to track the movement of goods in real-time. Combined with robotic automation, this creates a highly efficient and transparent system for managing complex logistics operations.

Supply Chain Robotics as a Service (RaaS): Robotics as a Service (RaaS) is a business model that allows logistics companies to rent robotic systems instead of purchasing them outright. This model provides flexibility, as businesses can scale their automation efforts based on demand without making significant upfront investments. RaaS helps businesses stay agile and take advantage of the latest robotic technologies without bearing the costs of ownership.

5. The Impact of Robotics on Workforce and Employment

While automation in logistics can drive efficiency, it also raises concerns about its impact on jobs. However, robotics is unlikely to completely replace human workers in the logistics industry. Instead, it will reshape job roles and create new opportunities. For example:

What is Collaborative Robotics (Cobots)? How They Work in Industries

-

Job Creation: Robotics will create new jobs in areas such as robotics programming, system maintenance, and technical support. Additionally, demand for employees with skills in AI, machine learning, and data analytics will increase as these technologies become more prevalent in logistics operations.

-

Job Transformation: While some manual jobs, such as order picking and packaging, may be automated, many workers will be required to oversee, maintain, and operate robotic systems. These roles will require different skills than traditional warehouse work, leading to the upskilling of the workforce.

-

Safer Work Environments: Robots can take on physically demanding and hazardous tasks, reducing the risk of injuries for human workers. For instance, robots can handle heavy lifting and navigate challenging environments, while human workers can focus on higher-level tasks that require decision-making and problem-solving.

6. Challenges and Considerations in Robotics Adoption

While robotics presents numerous advantages for the logistics industry, the transition to automation is not without challenges. Some key considerations include:

Initial Investment: Robotics technologies can be costly to implement, particularly for small and medium-sized logistics companies. The upfront investment required for robotic systems, including hardware, software, and integration, can be a significant barrier.

Integration with Existing Systems: Logistics companies must ensure that their existing operations can seamlessly integrate with robotic systems. This may require upgrading legacy infrastructure or adapting processes to accommodate automation.

Regulatory and Safety Concerns: The widespread use of robots in logistics raises regulatory and safety questions, particularly in relation to autonomous vehicles and drones. Ensuring compliance with local laws and maintaining safe working environments will be crucial to the successful deployment of robotic technologies.

Public Perception: The rise of robotics in logistics may generate concerns about job displacement and the future of work. It will be important for businesses and governments to communicate the benefits of robotics and ensure that workers have access to training and opportunities to adapt to new roles.

The Future of Robotics in Logistics

The role of robotics in transforming the logistics industry is undeniable. By automating critical tasks such as inventory management, order picking, and last-mile delivery, robotics is driving efficiency, reducing costs, and improving customer satisfaction. While challenges remain, the long-term benefits of robotics in logistics are substantial, including increased productivity, reduced labor costs, and safer work environments.

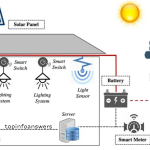

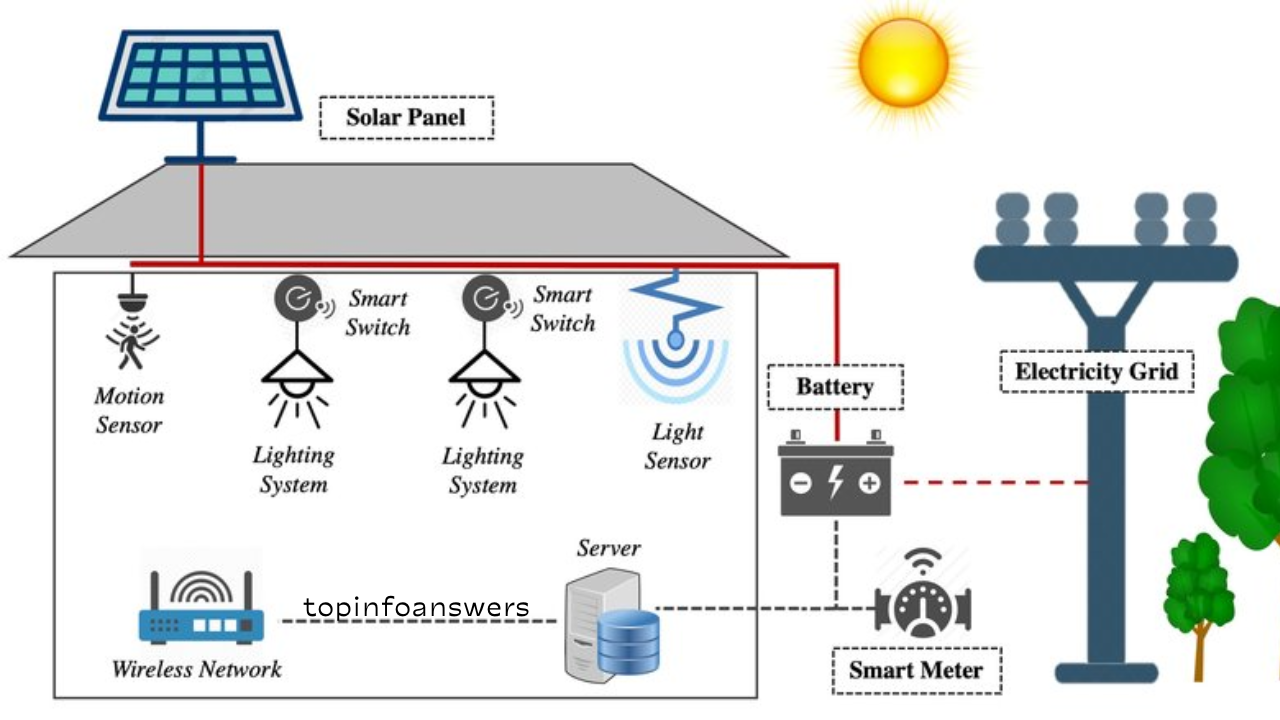

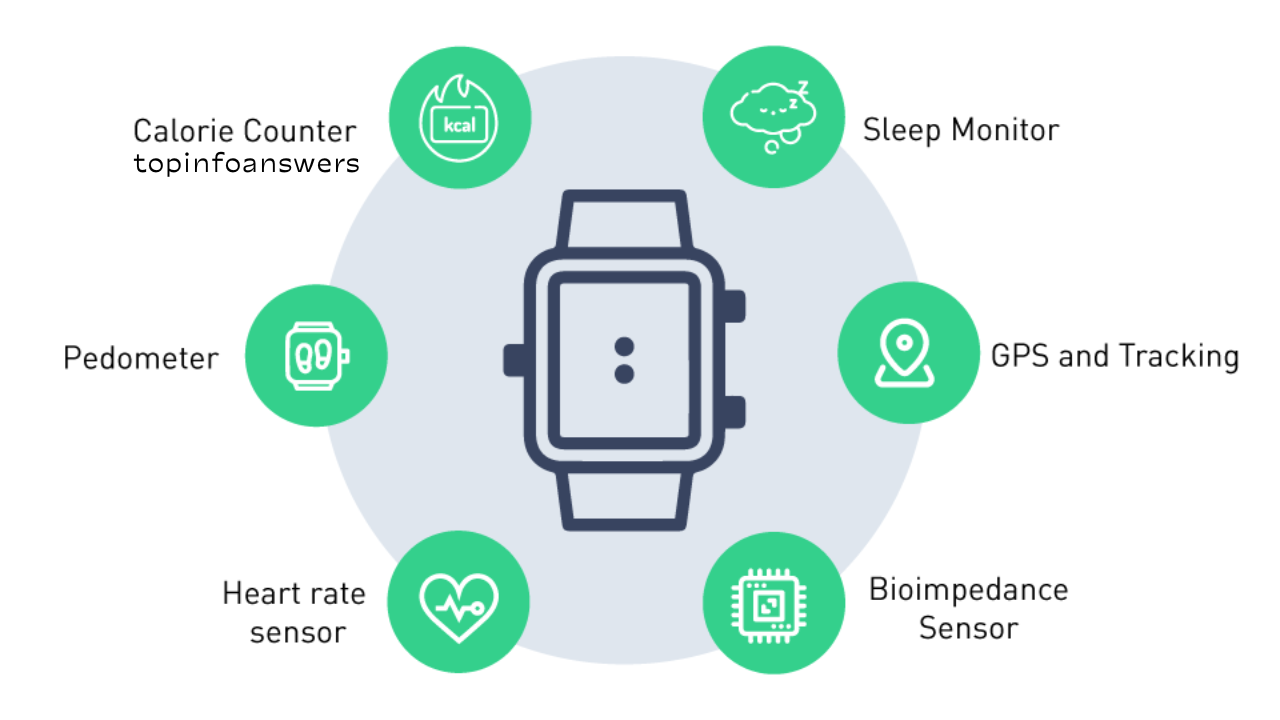

As robotics technology continues to evolve, we can expect further innovations in the logistics sector, such as more advanced autonomous vehicles, AI-powered sorting systems, and even greater integration with the Internet of Things (IoT). These advancements will continue to revolutionize the logistics industry, creating new business models and opportunities for companies and workers alike.

In the coming years, the logistics industry will likely see greater reliance on robotics to meet the increasing demands of the global economy, with robots complementing human labor rather than replacing it. As automation becomes an integral part of logistics operations, the future of this sector looks highly automated, efficient, and connected.