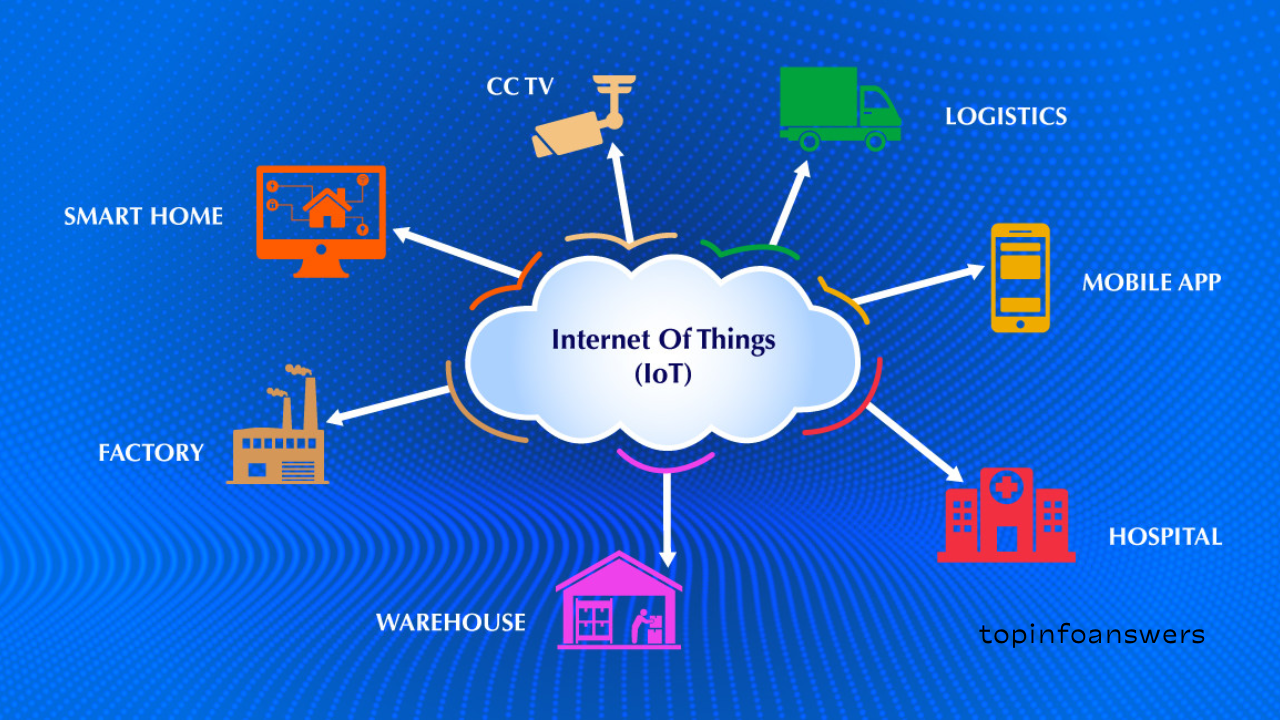

The Internet of Things (IoT) is revolutionizing industries worldwide, and supply chain management is no exception. By integrating IoT technology into logistics, warehousing, and transportation, businesses are experiencing unprecedented efficiency, cost savings, and real-time visibility. This article explores how IoT is transforming supply chain management, the benefits it brings, and the challenges that must be addressed to maximize its potential.

Understanding IoT in Supply Chain Management

IoT refers to a network of interconnected devices that communicate and share data over the internet. These devices include sensors, RFID tags, GPS trackers, and smart machines that help monitor and manage various supply chain processes. By leveraging IoT, businesses can optimize operations, reduce inefficiencies, and improve decision-making.

Benefits of IoT in Supply Chain Management

1. Real-Time Visibility and Tracking

One of the most significant advantages of IoT in supply chain management is real-time tracking. IoT-enabled GPS devices and RFID tags allow businesses to monitor shipments, inventory, and assets in transit. This helps in reducing losses, ensuring timely deliveries, and increasing overall efficiency.

Example: A logistics company can use IoT-enabled GPS tracking to monitor the movement of trucks and adjust routes based on real-time traffic data, minimizing delays and fuel consumption.

2. Predictive Maintenance

IoT-powered sensors can continuously monitor equipment and machinery, detecting potential failures before they occur. Predictive maintenance helps reduce downtime, minimize repair costs, and ensure smooth operations.

Example: A manufacturing plant can use IoT sensors to track the performance of conveyor belts and schedule maintenance before a breakdown disrupts production.

3. Improved Inventory Management

IoT enables businesses to track inventory levels in real-time, preventing stockouts or overstocking. Smart shelves equipped with IoT sensors can automatically update inventory counts and trigger replenishment requests when necessary.

Example: Retailers like Walmart use IoT to track stock levels and automate restocking processes, ensuring optimal inventory availability.

4. Enhanced Supply Chain Security

IoT plays a crucial role in improving supply chain security. Smart locks, temperature sensors, and geofencing ensure that products remain secure and meet compliance requirements.

Example: Pharmaceutical companies use IoT to monitor temperature-sensitive medications during transit, ensuring they remain within the required temperature range.

5. Increased Efficiency and Cost Savings

By optimizing transportation routes, reducing waste, and minimizing human errors, IoT leads to increased efficiency and cost savings across the supply chain.

Example: IoT-powered fleet management systems help logistics companies optimize fuel consumption and reduce operational costs.

Key Applications of IoT in Supply Chain Management

1. Smart Warehousing

IoT-powered warehouses utilize automation, robotics, and connected devices to streamline inventory management, order fulfillment, and storage optimization.

- Automated guided vehicles (AGVs) transport goods within warehouses efficiently.

- IoT sensors help in maintaining optimal storage conditions.

- AI-powered analytics predict demand and adjust inventory accordingly.

2. Cold Chain Monitoring

For industries dealing with perishable goods, IoT ensures that products are stored and transported under optimal conditions.

- Temperature and humidity sensors monitor perishable items.

- Real-time alerts notify managers of any deviations.

- Smart packaging solutions enhance product integrity.

3. Fleet Management and Logistics

IoT enhances fleet management by providing real-time data on vehicle performance, fuel usage, and driver behavior.

- GPS tracking optimizes delivery routes.

- Sensors monitor vehicle health and prevent breakdowns.

- AI-powered analytics improve scheduling and dispatching.

4. Supplier and Vendor Management

IoT helps businesses maintain a transparent and efficient supply chain by improving collaboration with suppliers and vendors.

- Blockchain-integrated IoT solutions ensure traceability.

- Automated data sharing reduces paperwork and delays.

- AI-driven insights help in making data-driven procurement decisions.

5. Demand Forecasting and Data Analytics

By leveraging IoT-generated data, businesses can make accurate demand forecasts and optimize supply chain operations.

- AI-powered analytics predict market trends.

- Machine learning algorithms optimize stock levels.

- IoT data enhances decision-making in procurement and production.

Challenges of IoT in Supply Chain Management

1. Data Security and Privacy Risks

With a vast amount of data being transmitted through IoT devices, businesses face significant cybersecurity threats. Hackers can exploit vulnerabilities and compromise supply chain operations.

Solution: Implement robust encryption, multi-factor authentication, and regular security audits to protect sensitive data.

2. High Implementation Costs

Deploying IoT solutions requires substantial investment in infrastructure, devices, and training.

Solution: Businesses can adopt a phased implementation strategy, focusing on high-impact areas first before scaling up.

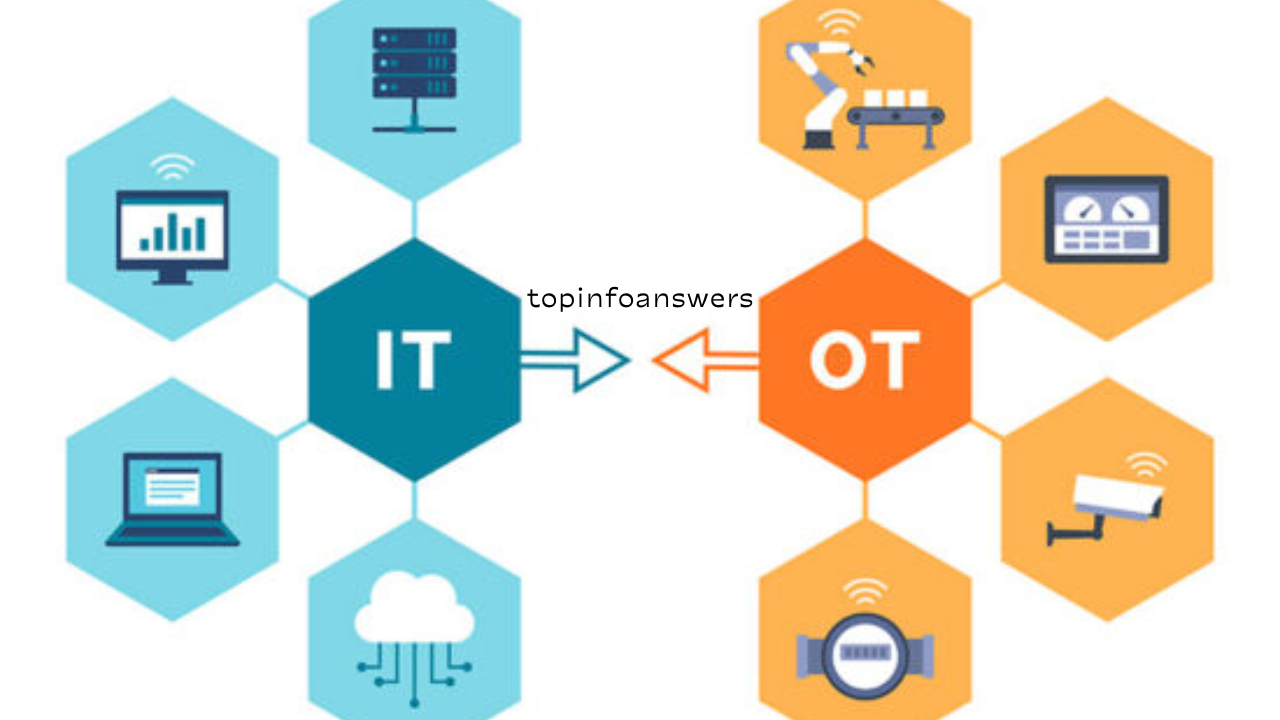

3. Integration with Legacy Systems

Many supply chain operations rely on outdated legacy systems that may not be compatible with modern IoT solutions.

Solution: Investing in middleware solutions and APIs can facilitate smooth integration between old and new technologies.

4. Data Overload and Management

IoT generates massive volumes of data, which can be overwhelming to manage and analyze effectively.

Solution: Utilizing AI-driven analytics and cloud-based data storage can help process and extract meaningful insights from IoT data.

Future of IoT in Supply Chain Management

The future of IoT in supply chain management looks promising, with advancements in AI, blockchain, and automation enhancing its capabilities.

1. AI and Machine Learning Integration

AI-powered analytics will further improve demand forecasting, anomaly detection, and supply chain optimization.

2. Blockchain for Enhanced Transparency

Combining IoT with blockchain will improve traceability, reduce fraud, and ensure ethical sourcing.

3. Autonomous Vehicles and Drones

IoT-enabled autonomous trucks and delivery drones will revolutionize last-mile logistics and reduce transportation costs.

4. Sustainability Initiatives

IoT will play a crucial role in promoting sustainability by reducing waste, optimizing energy consumption, and minimizing carbon footprints in supply chains.

IoT and Big Data: How They Work Together to Improve Business Insights

IoT is undoubtedly transforming supply chain management, offering enhanced visibility, efficiency, and security. While challenges exist, businesses that embrace IoT-driven solutions will gain a competitive advantage in today’s fast-paced market. By investing in smart technologies, integrating AI-driven analytics, and prioritizing data security, companies can build resilient and future-ready supply chains. As technology continues to evolve, the role of IoT in supply chain management will only become more critical, paving the way for a smarter and more efficient global supply network.