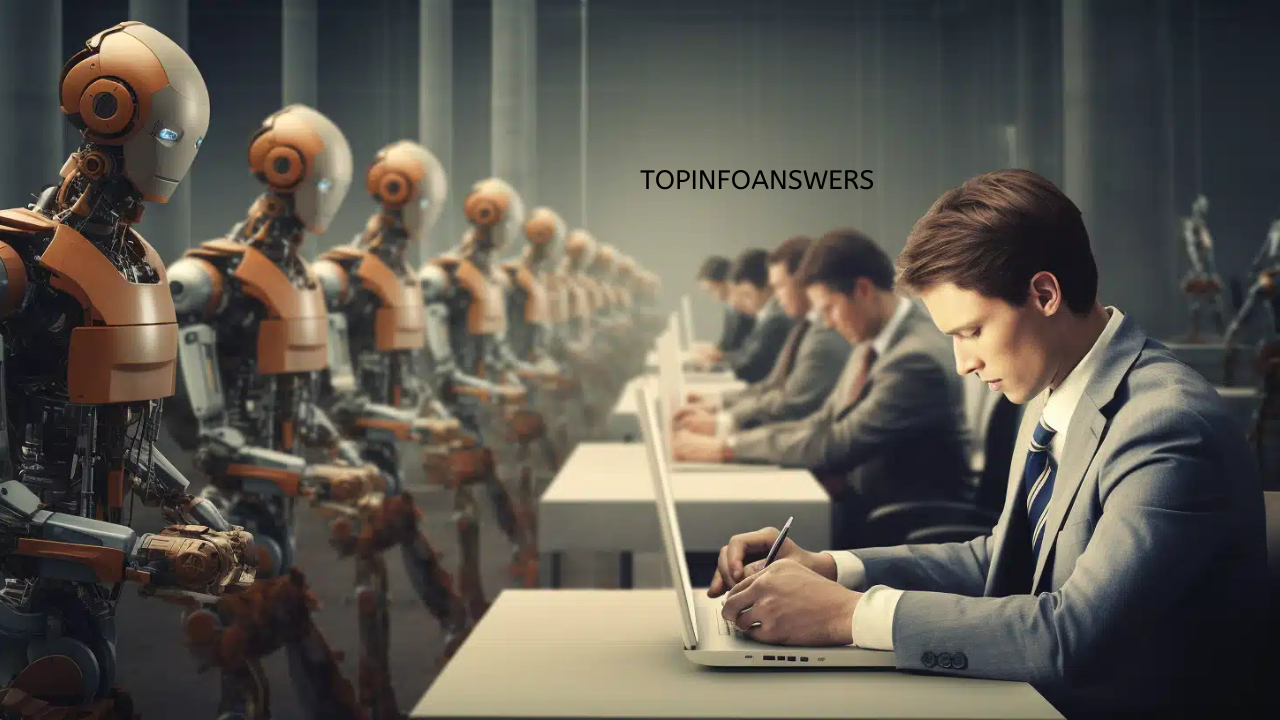

The rapid advancement of robotics and artificial intelligence (AI) has sparked discussions about their impact on job markets and employment. While some experts argue that automation will lead to massive job losses, others believe it will create new opportunities and enhance productivity. The truth likely lies somewhere in between. This article explores how robotics is transforming industries, the potential risks and benefits, and how workers can adapt to the evolving job landscape.

The Rise of Robotics in the Workforce

Robots are becoming an integral part of various industries, from manufacturing to healthcare. The increasing sophistication of robotics has led to their adoption in tasks that were traditionally performed by humans. Some key sectors where robotics is making a significant impact include:

- Manufacturing: Industrial robots are already widespread in factories, handling repetitive tasks like assembly, welding, and packaging. Companies such as Tesla and Toyota have integrated robotic systems to streamline production lines, improving efficiency and reducing costs.

- Healthcare: Robotics is revolutionizing the medical field, assisting in surgeries, patient care, and diagnostics. Surgical robots like the Da Vinci system allow for precision operations with minimal invasiveness, improving patient outcomes.

- Retail and Warehousing: Companies like Amazon and Walmart use autonomous robots to sort, package, and transport goods. Warehouse robots reduce delivery times and improve inventory management.

- Agriculture: Automated tractors, drones, and robotic harvesters are transforming farming practices, enhancing crop yields and reducing reliance on manual labor.

- Transportation: Self-driving cars, trucks, and drones have the potential to reshape logistics and transportation industries. Autonomous vehicles could reduce accidents and increase efficiency.

The Impact on Employment

Job Displacement vs. Job Creation

One of the primary concerns surrounding robotics is job displacement. As automation takes over repetitive and manual tasks, certain jobs will inevitably become obsolete. However, history has shown that technological advancements also create new employment opportunities. The Industrial Revolution, for example, initially led to job losses in agriculture but ultimately resulted in the creation of new industries and professions.

Types of Jobs Most at Risk

Some jobs are more susceptible to automation than others. Routine, predictable, and repetitive tasks are the most vulnerable. These include:

- Manufacturing and assembly line workers

- Cashiers and retail clerks

- Data entry and administrative jobs

- Customer service representatives

- Truck and taxi drivers

While these roles face a high risk of automation, jobs requiring creativity, critical thinking, and human interaction are less likely to be replaced.

New Job Opportunities Created by Robotics

On the flip side, robotics is generating demand for new skill sets and job roles. Some emerging careers include:

- Robotics engineers and technicians – Designing, programming, and maintaining robotic systems.

- AI specialists and data analysts – Developing and optimizing AI algorithms.

- Healthcare robotics operators – Assisting in robotic-assisted surgeries and rehabilitation.

- Ethics and compliance officers – Ensuring responsible AI and robotics usage.

- Cybersecurity experts – Protecting robotic systems from cyber threats.

The Shift in Skill Requirements

As robotics becomes more prevalent, the skills required in the job market are shifting. Employees must adapt to remain competitive. Some key areas of focus include:

- STEM (Science, Technology, Engineering, and Mathematics) Skills: Proficiency in robotics, coding, and AI will be increasingly valuable.

- Problem-Solving and Creativity: Jobs that require innovation and strategic thinking are less likely to be automated.

- Emotional Intelligence and Soft Skills: Roles involving interpersonal communication and empathy, such as healthcare and customer service, will still require a human touch.

- Lifelong Learning and Adaptability: Continuous education and upskilling will be essential to keep up with evolving technologies.

Economic and Societal Implications

Increased Productivity and Economic Growth

Robotics can lead to higher productivity, lower production costs, and increased economic growth. Businesses can scale operations more efficiently, leading to lower consumer prices and improved standards of living.

Income Inequality and Wage Gaps

One concern is that automation could widen the gap between high-skilled and low-skilled workers. Those with technical expertise may see wage increases, while others could struggle with stagnant wages or job displacement.

Potential for a Shorter Workweek

As robots handle more tasks, some experts suggest that humans could shift to a shorter workweek, with more time for leisure and personal development. However, this would require significant economic and policy changes.

Government and Business Strategies for Adaptation

To navigate the impact of robotics on employment, governments and businesses must implement strategic policies. Some possible solutions include:

- Education and Workforce Development: Governments should invest in STEM education, vocational training, and lifelong learning programs.

- Reskilling and Upskilling Initiatives: Companies should provide training programs to help employees transition into new roles.

- Universal Basic Income (UBI): Some propose UBI as a solution to offset job losses caused by automation, providing financial security.

- Public-Private Partnerships: Collaboration between governments, industries, and educational institutions can create job opportunities and support displaced workers.

The rise of robotics will undeniably reshape job markets and employment. While automation poses challenges, it also brings new opportunities for innovation and growth. The key to a successful transition lies in adaptability, education, and proactive policies. By embracing technological advancements and preparing for the future, workers, businesses, and governments can harness the benefits of robotics while mitigating potential risks.